Our Solar Powered Aerator Solution

Mix the “Good Old” British Weather with Global Warming and what do you get?

The short answer is the most unpredictable weather system we’ve ever known, veering from torrential rain one minute, to months-and-months of no rain at all, with water levels dropping, spelling danger for our fish stocks. We’ve seen our small pool (which is shallower than our large pool) completely dry up as recently as summer 2022. Nature is clearly serving notice, and we have to listen!

Like any other Angling Club with a facility like Hunters Pool, the members and committee were constantly concerned about the Summers ahead, usually from about March onwards. Yes, of course, we want those glorious summer days on the banks, but we don’t want to see any fish in distress or, worse, floating lifeless on the surface. So, we’d talked about it and, in Winter 2022, we decided to be proactive and try and protect our beautiful pools and our fish, via an Aerator, pumping air bubbles into our water when it needs it the most but, we had several problems to overcome…

1) We have no power at, or near, Hunters Pool.

2) Summer is when we need the Aerator deploying.

3) Around Hunters Pool, we have neighbours who we respect and rely on, so we can’t have the noise of a diesel generator disturbing them – especially in summer, as they would more-than-likely have their windows open.

4) External USB Voltmeter so we could monitor the battery voltage without removing the cover to the whole system.

5) Test button so we can ensure the system was fully operation (at a reasonable hour!)

6) We are only a small club and, therefore, our income means a restricted budget – typically, with much of our member income, we increase our fish stocks. This year, all monies we had available were allocated to solving our problem.

7) Whatever solution we deploy has to have low, ongoing, running costs.

8) The solution has to have longevity. We simply can’t construct it, and, when it’s needed the most, breakdown – so all the elements have to be of a robust, professional quality and environmentally sound.

9) The members (and any available friends) need to complete the project themselves, allowing us to get the best solution for our constrained budget.

10) When the bad weather sets in (i.e. Winter), we need to be able to remove parts that can deteriorate when not in use like as the Solar panel and Batteries, whilst retaining the integrity of the operational end in that remains in the water. So, we have to have a manual way to clear the diffuser heads without power.

The photos above are: Craig Watson-Parke, Andy Grimshaw, Our Control Unit, part of the team including Pete Boyce.

We initially looked at all the on-the-shelf solutions and quickly worked out they were simply beyond our financial reach. After some brainstorming, initial designs and then design reviews, we decided on getting together the members capable of perfecting the design and constructing a solution and sounded out some “genius” friends too. After they all agreed, we set up a WhatsApp group to communicate and started with a few Zoom meetings, to present the problem, pencil a solution and estimate the amount of money we could spend on it. As Treasurer, I was the money man, Craig Watson-Parke, the engineer tasked with putting it all together, Stu Drabble built the structure, Pete Boyce took on the overall Project Management, Andy Grimshaw started designing the final Aerator system as well as bespoke solutions. Che Scott was “press-ganged” into 3D printing items that we couldn’t buy and supplying the PeliCase to house it all, latterly the project was helped along by Paul Abela who painted the structure and Pete Turner and Paul Davies, who stepped in to help Craig when he injured his hand. We then broke the problem down and worked out the component parts we needed…

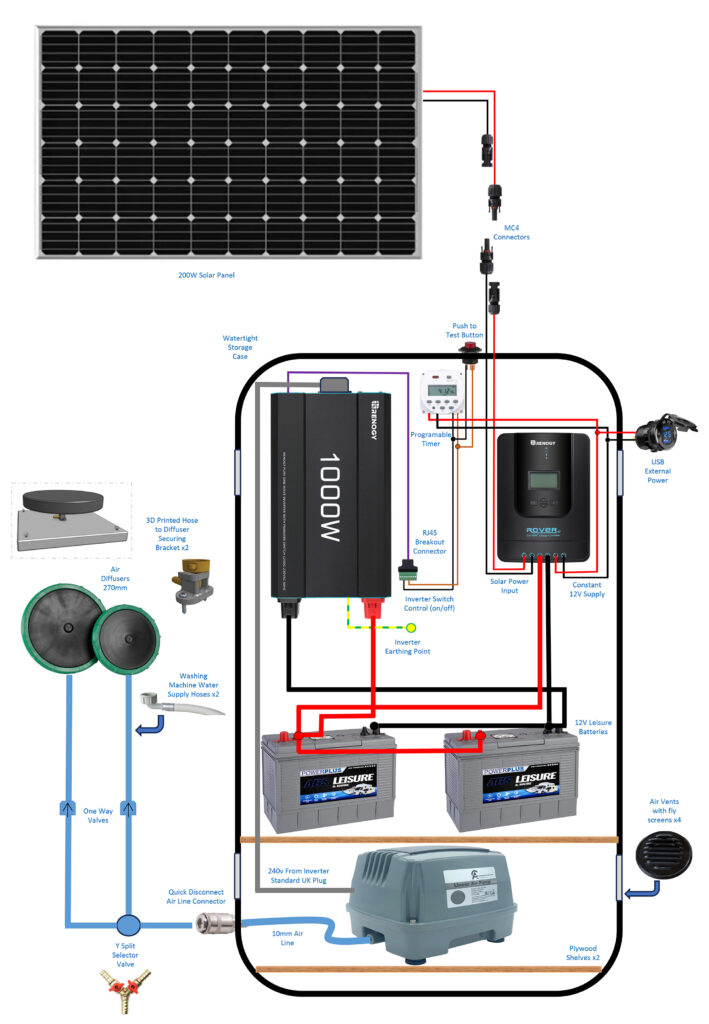

1) Solar Panels to collect the power. Once up and running, a no-cost, silent, environmentally friendly solution. They were specified to be removable for winter storage so as not to be a problem during strong, autumn/winter, winds.

2) Batteries (2) to store the power collected during the daylight hours and release it when needed.

3) Timer so the Aerator can operate at the optimum times – it has to be operational when the water Oxygen levels are at their lowest – typically just prior to sunrise.

4) A case to store the control elements that is both secure (lockable) and waterproof.

5) A secure structure to attach all the above to, built so it is accessible and not impeded by foliage or trees.

6) A pump that can expel air at the rate we need it to.

7) Air hoses, taking the air to the centre of our large pool. They have to be heavier-than-water, so they sink into our silty bottom, avoiding getting snagged on fishing gear (especially feeders). The hoses that are on the bank before they enter the water also have to be buried, avoiding a trip hazard, – we have several, more mature, members and some with mobility issues.

8) Diffuser heads, big enough to expel enough air to protect our fish.

9) Marker Buoys so every angler knows where they need to avoid, both where the final diffusers are, but also giving them an idea where the hoses run (hopefully).

10) Warning labels to stop anyone touching the set up, potentially breaking it, or hurting themselves.

We fine-tuned our budget and did a presentation and announced it to our full membership, firstly at a meeting and then via our other communication channels, ensuring we informed everyone what we were proposing and, thankfully, we got their full support. We also showed them our “starting” shopping list and called for any help people they could give, in terms of work, donating items and, ultimately donating money too.

Our initial budget was £1,000, but, true to the fabulous support of our members, we had another £220 donated specifically towards this project – and, we really did need the extra money! That said, the PeliCase was donated by Che – a fabulous gift that meant we didn’t’t have to spend upwards of £600 on a unit to house the operational items. However, if any other organisation wants to replicate this, it’s worth pointing out that these units need to be in a secure, waterproof environment, so a “hut” or “shed” would serve a similar purpose, assuming they were in the correct location for the system.

The “wiring” diagram shows how it all works and the table shows the items we purchased and where we got them from, minus the PeliCase, which, as mentioned was thankfully was donated. The items we engineered ourselves were made from CAD drawings and then 3D printed, these are available on request, Free of Charge, of course.

Although it is starting to appear we won’t have to rely on our Aerator this year, our worry has ceased and we can relax in the knowledge we’ve done as much as we can up until now to protect our facility and fish.

WINTER UPDATE

Mid-September, we removed the Solar Panel and Batteries and stored them for the Winter. We then needed to ensure we could clear mould and bacteria from the holes in the diffuser heads over Winter ready for use in the New Year, so we rigged up a standard 10mm garden hose with the valve of a bike inner tube inserted and clamped in place with a jubilee clip. It is connected to the aerator splitter connector. (It works well doing both at the same time but can be adjusted to one at a time if required) normal bike pump connected to the valve. The bike pump is stored on top of the PeliCase and we’ve simply asked those members that are at Hunters to push the bike pump about 20 times, or until air starts to surface from each Diffuser. It’s incredibly simple, but works a treat!

Out of our £1,220 budget, we spent £1,190.69, bringing it in £29.31 under! For once, luck was on our side.

A huge thank you to everyone involved! We now have a system that will benefit us and our fish for years to come.

Our Shopping List looked like this…

Copyright in this website and all the information contained within it is the confidential and proprietary information of Windmill Angling Club. It is not to be reproduced in whole or in part without the prior written permission of Windmill Angling Club. Neither shall it be used otherwise than for the purpose for which it was originally intended.